POP Module 5 - Farm Staff Applications

Applications and Research Integration

Discover how POPs enable modern agricultural research, support farm operations, and align with NMSU's strategic vision for innovation and outreach

Learning Objectives

By the end of this module, you will be able to:

Applications for Farm Staff and Operations

POP connectivity transforms how farm staff work in the field, enabling real-time communication, remote monitoring, and data-driven decision making. These applications directly improve operational efficiency and safety.

Field Communication and Coordination

Voice and Video Calls:

- Staff can communicate with office/supervisors from remote fields

- Video calls enable visual problem-solving (equipment issues, crop concerns)

- Reduces need for physical travel back to office for consultations

- Emergency communication capability in case of injury or equipment failure

Messaging and Collaboration:

- Real-time text messaging for quick questions and updates

- Share photos of field conditions, pest damage, or equipment status

- Access shared documents and work orders in the field

- Coordinate activities across multiple field locations

Real-World Example:

Farm manager notices unusual pest activity in alfalfa plot. Takes photo with smartphone, sends to extension agent via WiFi from POP coverage area. Agent identifies pest and recommends treatment within 15 minutes—preventing crop damage and avoiding unnecessary pesticide application.

Surveillance and Security Cameras

Equipment and Asset Protection:

- Monitor expensive equipment (tractors, implements) in remote locations

- Deter theft and vandalism with visible camera presence

- Review footage after incidents to identify perpetrators

- Reduce insurance costs with documented security measures

Operational Monitoring:

- Observe livestock behavior and health from office

- Monitor irrigation systems for leaks or malfunctions

- Check field conditions without physical site visits

- Time-lapse recording of crop growth and development

Camera System Integration:

POPs can support multiple IP cameras via WiFi or ethernet. Typical setup: 2-4 cameras per POP, streaming to network video recorder (NVR) at main building. Cameras can be solar-powered or powered from POP's battery system.

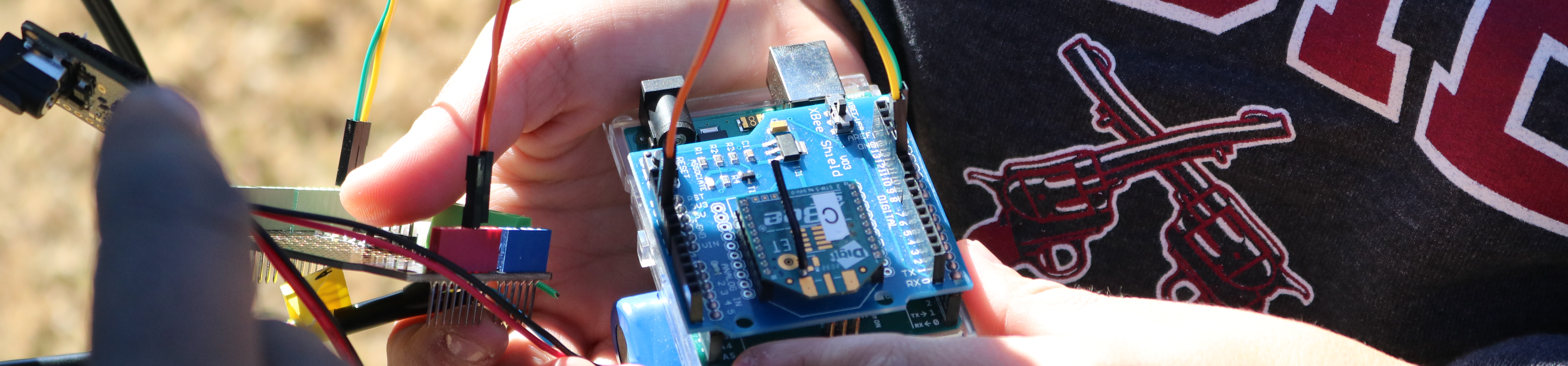

IoT Sensors and Monitoring Devices

Environmental Sensors:

- Weather stations: Temperature, humidity, wind speed, rainfall

- Soil moisture sensors: Optimize irrigation scheduling

- Soil temperature probes: Track growing degree days

- Light sensors: Monitor solar radiation and photoperiod

Irrigation Management:

- Flow meters: Track water usage and detect leaks

- Pressure sensors: Monitor system performance

- Remote valve controls: Start/stop irrigation from office

- Tank level sensors: Monitor water storage

Equipment Monitoring:

- GPS trackers: Locate equipment and track usage hours

- Fuel level sensors: Prevent theft and optimize refueling

- Engine diagnostics: Predictive maintenance alerts

- Gate sensors: Track access to secure areas

Operational Benefits:

IoT sensors connected via POPs eliminate the need for manual data collection trips. Staff can monitor conditions in real-time from any location, receive alerts for out-of-range values, and make data-driven decisions. This saves time, fuel, and improves responsiveness.

Mobile Device Support

Smartphones and Tablets:

- Access email and documents in the field

- Use farm management software and apps

- GPS navigation to field locations

- Photo/video documentation of field conditions

Specialized Equipment:

- Precision agriculture tablets (e.g., John Deere Operations Center)

- Handheld soil testing devices with WiFi upload

- Drone controllers for aerial imaging

- Livestock management scanners (RFID readers)